Zambelli has maintained in years of business a leading presence in the food industryboth in cardboard packaging and in packaging containers with LDPE film.

Being in the vanguardrequire a great technical commitment to constantly update both technologies, with experimentsverydifferent from each other; for example: for the case packers in the high speed handling of the dies, for the shrinkwrappersinstead the reduction of the thermal dispersion of the furnace.

It’s easy to understand the enthusiasm with which Zambelli hasinvested in a new technology suchasRoboticsthathasbeenshown to be appliedequallywell for the Food industry in bothcase packers and shrinkwrappers.

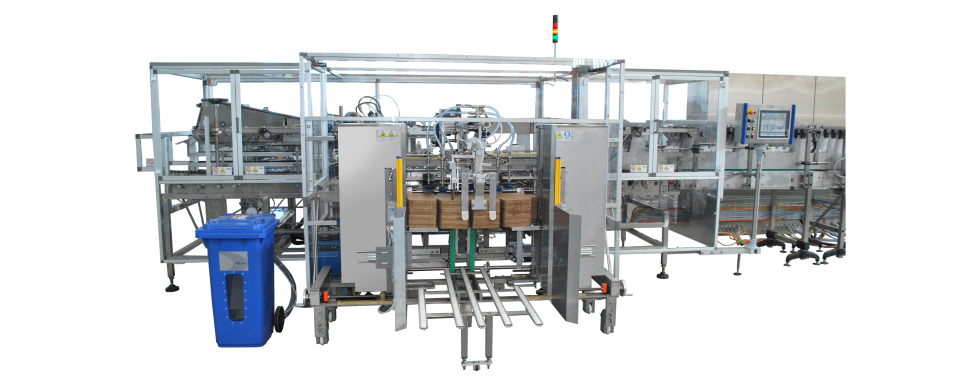

Case packers

Zambelli usesrobots of varioustypes – from anthropomorphic to delta robots – according to the size and weight of the food product to be introduced inside american case or wrap-around.

An exampleiscertainly the wrapping machine for ricotta trays made for a french multinational. In this application, roboticshas made itpossible to adapt the template of the packer to an available space reduce and conformed in an unconvetional way, butnotonly: the range of the robot usedhasalsoallowed to fill more packers for eachcycle, allowing to reach the high production rate required by the line.

In this way the robotiz ationincreases the flexibility of the case packerswithoutpenalizingits performance. Anotherimportant benefit is the maximum accessibility to allareas of the machine in the control and maintenance phase, as the traditional pushersconnected to the structureisreplaced by the robots gripping body.

Shrinkwrappers

In shrinkwrappers, robotic shas been applied by Zambelli to achieve different objectives, including: the positive manipulation of unstable containers that cannot be pushed or accumulated in a traditional way, the possibility of making system flexible, not only in many formats, butalso in different packaging materials, moving from packaging card board to packaging containers with LDPE film.

An example of containers thatcannot be accumulatedis the robotized shrinkwrapper to package tapered cups of confectionery product, delivered to an american multinational: the small spilledtaperedcups, in this case, are taken from the robot’ssocket head and deposited directly into the tray, whic his then wrapped with LDPE film.

A robot built-in the Zambelli tapered cups packin gallows to keep small the system footprint and shorten the distance between picking and placing positions of the containers all to the benefit of efficiency and reliability.

Case packers and shrinkwrappers

For another american multinational, Zambelli has been able to create a compact system where the robot carries out the task of supplying, to a shrinkwrapper and a case packer, small jars of spices with a characteristicbulbshape, whichmakesthemverydifficult to manipulatewithoutfalling.

The possibility offered by roboticsto pick and place with freedom the product, has allowed to combine two packaging machines with different packaging materials – cardboard and LDPE film – to the same supply.

Daniele Toni

Daniele Toni