INTERPACK 2017 - Italian exhibitors

-

-

Tworth

Tworth

A new concept for conveying food products that solves the problem of lubrication, raises the level of hygiene and ensures concrete advantages.

It's not simply a conveyor belt, but a patented system we've manufactured enitrely in our factory. Built entirely in stainless steel, but with sliding blocks and sliding profiles in plastic material, the conveyor belt guarantees prolonged resistance over time without wear.

-

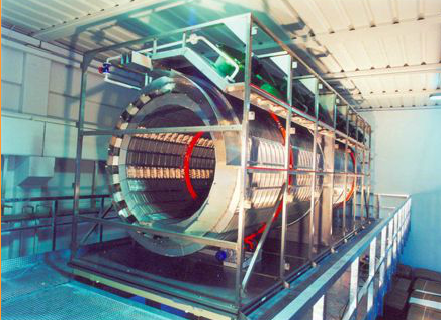

Deep-Freezing

Deep-Freezing

A sector that is expanding fast deserves our best technology. The know-how we continue to acquire helps us guarantee the best

technical solutions for the treatment of packaged or bulk food products: a state-of-the-art process that allows users to preserve the natural aroma, color and flavor of food products intact.

-

Cooling

Cooling

The flexibility of our technology is such that we can develop plants for both ambient cooling and forced-air room cooling: each with distinctive features, each with specific advantages.

-

Pasteurizing

Pasteurizing

The heating step during the pasteurizing sequence is not only important: it is crucial. For this reason, our plants use convection heating to ensure uniform and quality results. And what's more, the option of differentiating the temperatures is the distinctive trademark of a plant built around the concept of flexibility.

-

Proofing

Proofing

Such a delicate process deserves all our attention: which is why we have always developed perfectly calibrated plants that do not alter the properties of the food products and which therefore respect both the end product and the consumer.

-

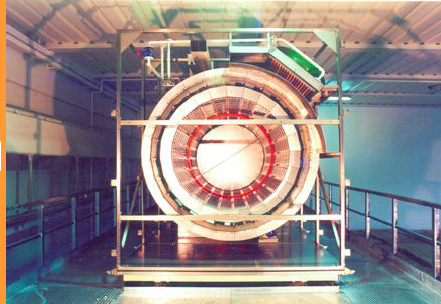

Baking

Baking

Industrial baking plants are usually tunnel-shaped!

Ours is spiral-shaped. A choice that may seem a counter-trend to the market, but is actually perfectly in line with those who are seeking advantages and performance.

-

Frying

Frying

Diathermic oil industrial fryer, with a conveying system studied for each product according to client requirements.

This allows us to satisfy the needs of even the most diversified sectors, such as meat, fish, breaded goods, snacks, peanuts, confectionery and pet food alike.

-

Product handling

Product handling

As an accessory for our spiral systems, we have developed conveyor belts and auxiliary components that allow us to complete product handling in all the phases of the production cycle, making the process automated exactly to the extent requested of by the customer.

As an accessory for our spiral systems, we have developed conveyor belts and auxiliary components that allow us to complete product handling in all the phases of the production cycle, making the process automated exactly to the extent requested of by the customer.

-

-

-

Special applications

Special applications

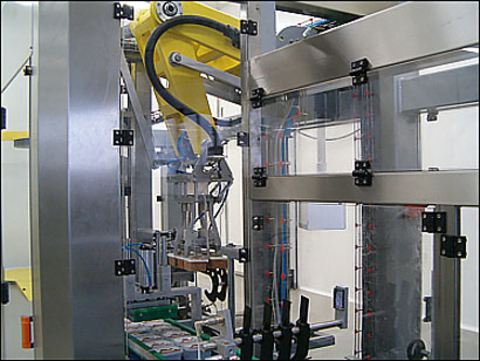

The expertise Abrigo has developed in robotic manipulation, product handling, and the integration of different technologies into a single system has allowed us to develop special applications, side-by-side with the customer. Where standard solutions were not sufficient to meet the manufacturing needs, Abrigo worked in full partnership with its customers, designing and creating ad hoc solutions based on the experience accumulated throughout its long history of industrial automation.

Collaboration continuity, attention to detail, and confidentiality are our guiding principles. We intend to remain on this path even in the future, with our new customers as well as our existing ones.

-

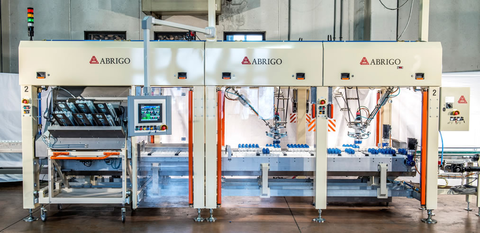

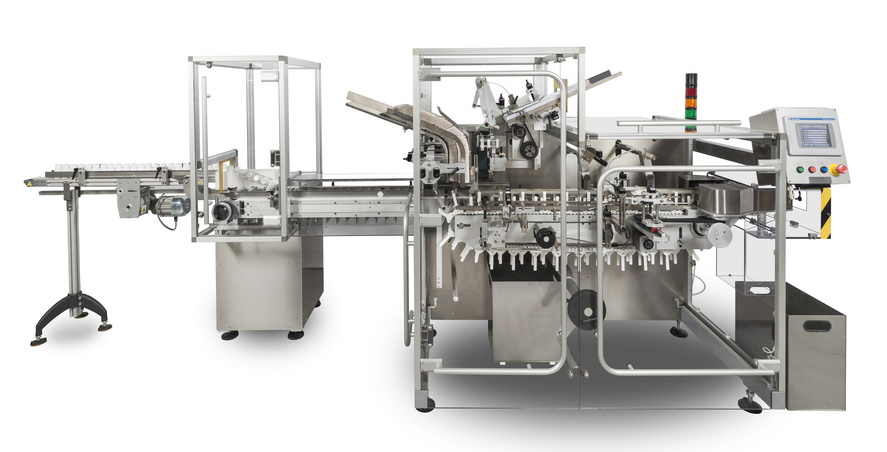

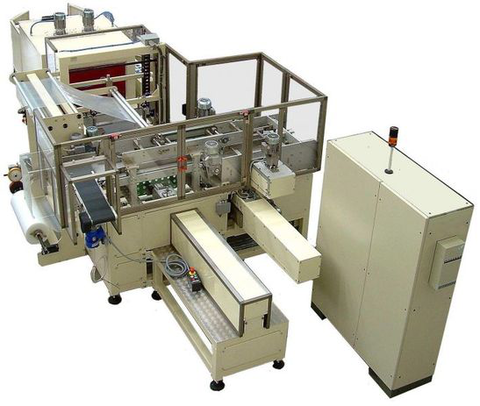

Flexible automation

Flexible automation

Abrigo has integrated new solutions to its secondary packaging machines, based on the concept Modular Robotic System

The today’s trends of food industry are oriented to a growing dynamicity. The products’ life cycle is getting shorter, the production lots smaller, and the variety packaging is a benchmark of marketing. For these reasons, for food companies it’s fundamental to have production lines which include high performance, efficiency and growing flexibility. Format changeover operations must be simple, quick, safe and without possibility of error. To match these requirements, Abrigo has integrated new solutions to its secondary packaging machines, based on the concept Modular Robotic System.

-

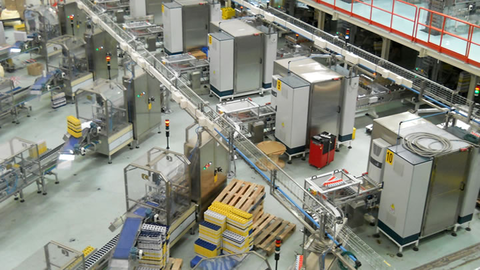

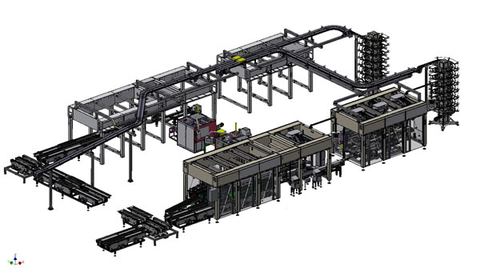

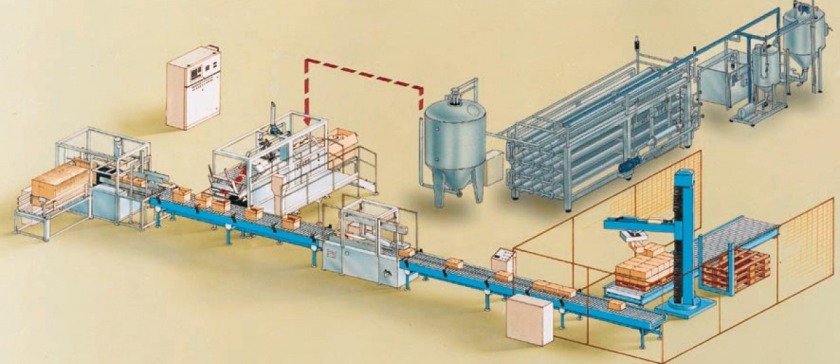

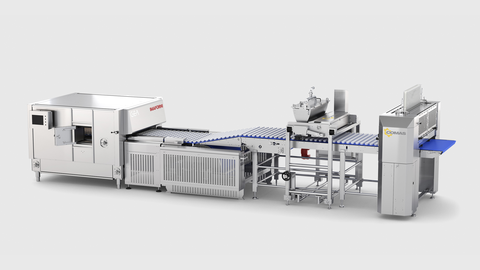

Complete custom lines

Complete custom lines

We design and build systems and lines to manage the entire automation from cutting to the end of the line.

Il Our goal is to provide "turnkey" solutions: modular technologies and unique, customized machines that are ready to adapt to pre-existing layouts.Our technologies can be integrated with each other or with our clients’ systems to create automated systems able to satisfy every kind of production need.

These solutions include all the equipment needed to connect the parts of the line, manage product flows, and perform quality checks at different stages of the production process.

-

-

-

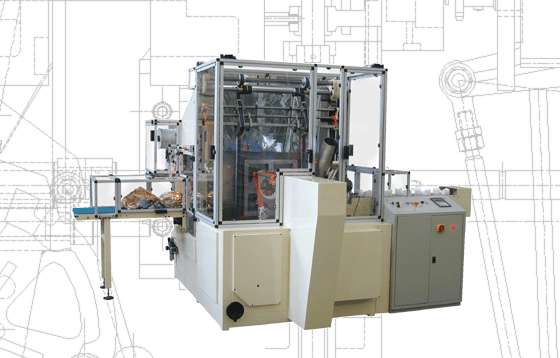

Wrapping machine and coining press for chocolate coins

Wrapping machine and coining press for chocolate coins

The machine is fitted with an aluminium foil cutting and coin wrapping group with two coining stations. This makes it possible to double coining time thus ensuring perfect execution even in the case of very strongly marked coinings. It saves up to 10% of aluminium foil when wrapping coins of 20 to 43 mm. Which is obtained with the cutting of two wraps from one single reel at the same time. With the simple replacement of one of the two reels it is also possible to obtain coins having sides of different

New version of the old M200 machine.

-

Cap Applicator - DOMINICI MT121

Cap Applicator - DOMINICI MT121

Automatic machine to apply plastic caps on packages and boxes of various sizes.

The caps are poured into a hopper in bulk, orientated and picked up continuously by the machine via suction cups. A hot-melt adhesive system allows an even layer of glue to be applied on the cap that is immediately applied with precision and pressed down on the package until it is perfectly bonded.

-

Chocolate EGG Wrapping Machine - Dominici LC 901

Chocolate EGG Wrapping Machine - Dominici LC 901

The egg, placed manually on the chain, is fed to the base loading station (with base picked up from a loader), the sheet cutter section (with wrapping material cut from a reel), the wrapping unit and the final tying area, with round string cut from a spool and fashioned into a bowknot.

Standard manual feeder chain with seven-egg capacity or customized as required. Fabrication of automatic loading devices also possible. Sheet prints centered through photocell thus option to operate with continuous or centered print reels. Simple format change, with just a few mechanical elements to be replaced and parameter settings from operator interface display.

-

-

-

RCFP1-T robotic Pick & Place

RCFP1-T robotic Pick & Place

RCFP1-T robotic Pick & Place monoblock with positive indexing collation device for bottlepack.

-

MA1 partition inserter for wine bottles

MA1 partition inserter for wine bottles

The machine inserts the partions between the bottles on the infeed conveyor of the case packer after separating groups of 12 or 6 bottles. With this system, the partitions are inserted between the bottles in a position where these are not subject to any pressure and therefore there is no risk of damaging labels or partitions.

The MA1 can be combined with an MCP casepacker equipped with apecial picking head for bottles with partitions.

-

RCFP1-T monoblock for packing plastic trays

RCFP1-T monoblock for packing plastic trays

RCFP1-T monoblock for packing plastic trays of ready meals and pre-cooked pasta sauce in shelf-ready cases.

-

-

-

-

Depalletisers - palletisers

Depalletisers - palletisers

DEPALLETTIZERS

The modular design of our depalletisers permits the production of machines with variable configurations, to suit our clients needs.

Our depalletisers model DAM90 have a double-column structure suitable for high speed installations. This structure is manufactured in 360 steel, painted with epoxy resins. The union surfaces and the sites supporting the movements are worked by CNC (computer numerical controlled) machine tool with numerical control to grant a perfect fluidity in the trolleys’ handling.

Our depalletisers are also equipped with programmable electronic equipment: this with the aim of granting the most complete flexibility during the working phases, controlling the various movements and giving to the operator the possibility of varying the operation parameters.

PALLETTIZERS

Our range of palletisers grants a high flexibility and can handle packs, cartons and plastic crates.

The machine’s main feature is a solid column, sustaining the lifting group upon which the device forming and position of the layer are located.

In the palletisers of the PABR and PAM series, the entrance of the products is from the bottom, with motionless pallet and vertical handling of the completed layers.

The palletisers of the PAM series can be equipped with a empty pallet magazine including pallet feeding rolling chain, automatic device to insert an interlayer sheet between the layers and driven pallet outfeed conveyor for finished pallet accumulation.

-

Shrink-wrapping machines

Shrink-wrapping machines

The shrink-wrapping machines are automatic lines for packing with thermoshrinking film are designed and manufactured in different models, according to the type of container, to the type of package (without any carton support, with lap or with tray) and according to the production capacity of the line.

-

Volumetric filling systems

Volumetric filling systems

This system is equipped with a set of pre-dosing pistons that take the product from the filling tank, positioned in the centre of the filler, and then dose it inside the container.

Thanks to this principle, the filling accuracy is very high.

-

-

-

Rice line

Rice line

The automatic ROTAXOR line is suitable to dry Quick Cook rice.

The rotary drum, together with the constant internal ventilation of the sectors, assures an homogenuous rice drying..png)

-

Pellet and Snack line

Pellet and Snack line

The automatic ROTAXOR line is suitable for the pellets, snacks and breakfast cereals drying.

The rotary drum, together with the constant ventilation inside the sectors, allow an homogeneous product drying. In particular, the homogeneous drying of pellets allows a very low percentage of wasted products during the following phases.

-

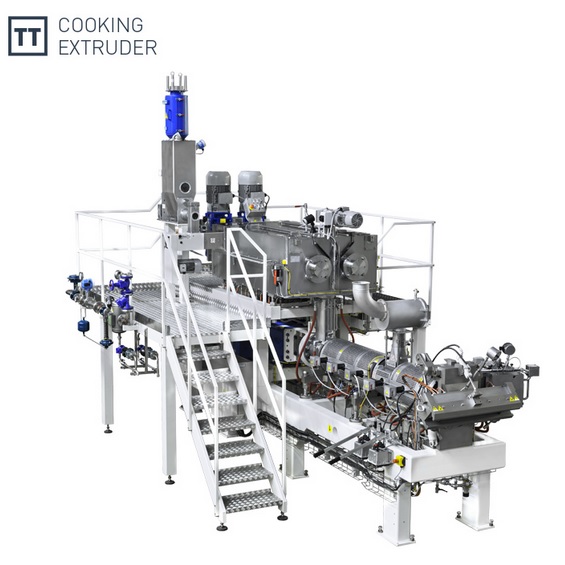

LPS – Special Shaped Pasta Line from 200 to 1200 Kg/h

LPS – Special Shaped Pasta Line from 200 to 1200 Kg/h

High temperature special shaped pasta line with capacities from 200 kg/h to 1200 kg/h suitable to output special shaped pasta on trays, such as nested pasta, lasagnas, cannelloni and large short cut pasta shapes.

High temperature special shaped pasta line with capacities from 200 kg/h to 1200 kg/h suitable to output special shaped pasta on trays, such as nested pasta, lasagnas, cannelloni and large short cut pasta shapes.- Press with vacuum tank and highly performing compression screws.

- Each machine is fitted with adjustable feet leveling the pasta line to any kind of floor

- Supporting frames are manufactured in stainless steel to grant stability and longer lifetime to the whole installation.

- High efficiency heating batteries with flanged connections.

- High density fiberglass panels lined internally with stainless steel sheet and silicone rubber gaskets.

- Hydraulic plant complete with 3-ways pneumatic valve, pump, by-pass, gauges and thermometers.

- Air exchange systems realized with stainless steel channels and butterflies equipped with air suction and air input electro-fans with pre-heating batteries.

- High efficiency axial fans with electric motors specially for High Temperature.

- Pasta trays manufactured in stainless steel and aluminum, complete with high resistance polyester mesh.

- Vertical pre-dryer fitted with high efficiency fans.

- Drying gallery fitted with vertical lifting/descending device for trays by means of PVDF guides.

- Motors fitted with high resistance transport chains.

- Storage trays section to allow a discontinuous packaging machine running.

- Independent motorized trays return.

- Ladders and handrails manufactured according to international safety rules.

- Electric control panel with automation by plc and supervision software through personal computer.

- Remote assistance via Internet.

.jpg)

-

-

-

Raw materials handling systems for the biscuit and confectio

Raw materials handling systems for the biscuit and confectio

Raw materials handling systems for the biscuit and confectionary industries; for both powder (such as flour & sugar) and liquids (animal/vegetable fats, etc.) from bulk receipt by tanker truck, big bags and containers via feeding systems, through to the storage, dosing, weighing and transport of products throughout the plant

All processes are managed by PLC with a PC interfaced monitoring system.

-

Handling equipment of milled products for the pasta industry

Handling equipment of milled products for the pasta industry

Handling equipment of milled products for the pasta industry, from bulk receipt of semolina by tanker truck with automatic feeding systems to the presses, through to storage, weighing, dosing, mixing and cleaning; Automatic micro-dosing of ingredients such as egg powder or liquids.

Plant sizes can vary with product flow rates from 1 to 10 tons / h.

All processes are managed by PLC with a PC interfaced monitoring system.

-

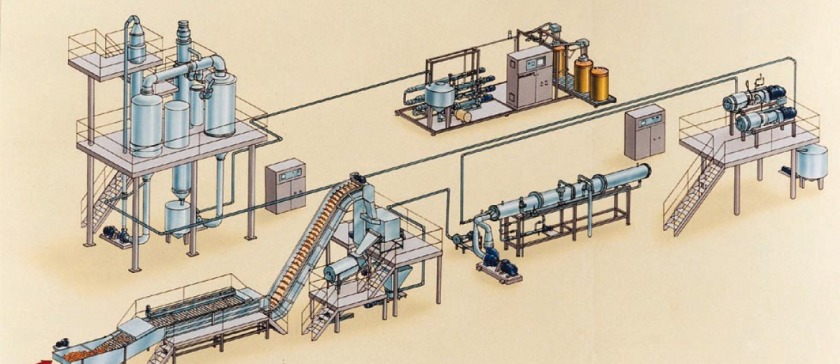

Equipment for the Coffee Industry

Equipment for the Coffee Industry

Brambati is also a leader with vast experience in manufacturing processing equipment for the Coffee Industry.

We can supply turn-keys plants for the coffee industry from the reception of green coffee, through to the feeding of packaging machines, with management systems for the different stages of cleaning, storage, weighing, blending, roasting, conveying (traditional mechanical transport or the new generation transport that uses high density at low-speed), grinding and degassing.

-

-

-

Filling units

Filling units

Caveco made filling unit for complete its packaging lines. We made most efficient solution filling units for liquid, semiliquid or solid products for all foods products like sauces, lasagne, meat, seafoods, dessert, dairy, fruits and vegetables.

Advantage of our sistem of automatization:- reliability of systems

- materials certified for food contact

- precision and flexibility

- touch-sceen user friendly

- Easy-Clean

- reduced costs of maintenance thanks to the excellent quality of the materials used

- over fourty years of experience

-

TEMA 45 & TEMA 70 Automatic Tray Sealer

TEMA 45 & TEMA 70 Automatic Tray Sealer

Automatic thermosealing machine mod. TEMA/45 pn is suitable for closure in MAP, in thermosealing «T» and SKIN of food products in trays with lid obtained from film reel and trimmed according to the tray shape and automatic film waste rewind system.

It is employed in all production fields, small and large companies, supermarkets, butcher shops, fish markets, fruit and vegetables, satisfying the necessary requirements of hygiene and cleaning of the food industry.

The sealing machine mod. TEMA is suitable for a wide range of food products: meat, fish, ready meals (fresh or frozen), vegetables (especialy salads), diary products, pasta, etc.

This machine is suitable in all sectors of the food industry, small and big companies, supermarkets, butchers, fish shops, etc. fulfilling the necessary hygienic and cleaning requirements of the food industry.

Completely made in stainless steel and anticorodal aluminium, all the surface and the parts that can get in contact with the product, tray and film, a proper program can be performed, stored and retrieved. The package size change (in case of more than one tray type) is very easy and fast.

-

Magic

Magic

MAGIC “Patent Pending” is a revolutionary machine able to recognize and pack different sizes of trays without tools change!

The automatic thermosealing machine mod. MAGIC is suitable for any packaging needs in protective atmosphere (MAP) of food products in preformed trays with compatible thermosealable film. The machine is expressly conceived for working in the food industry.

The thermosealer mod. MAGIC is able to work in the following ways :- only sealing: it is able to seal trays in material plastic, aluminum or coupled cardboard.

- in vacuum and in vacuum + Gas (MAP): to seal trays in material plastic, aluminum or coupled cardboard.

- with SKIN system: the system allows to create, with the use of a specific film for this application, a skin effect inside a preformed tray, with the film perfectly following the shape of the packaged product.

-

Complete Packaging lines from premade trays

Complete Packaging lines from premade trays

CA.VE.CO.'s core business is made from complete lines for filling and packaging sauces, lasagne, meat, seafoods, dessert, dairy, fruits and vegetables. We can supplie tailor made implant.

Advantage of our sistem of automatization:

- reliability of systems

- materials certified for food contact

- precision and flexibility

- touch-sceen user friendly

- easy-Clean

- reduced costs of maintenance thanks to the excellent quality of the materials used

- over fourty years of experience

-

-

-

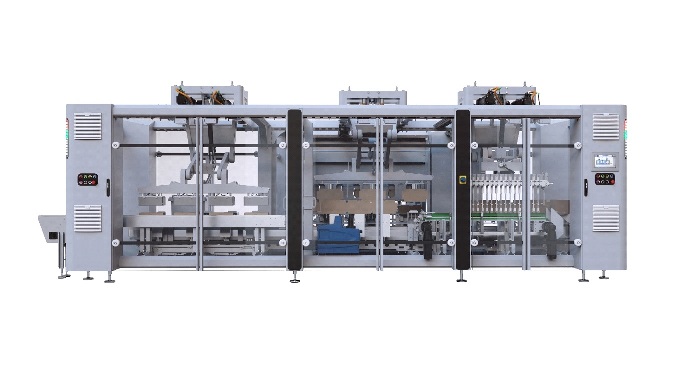

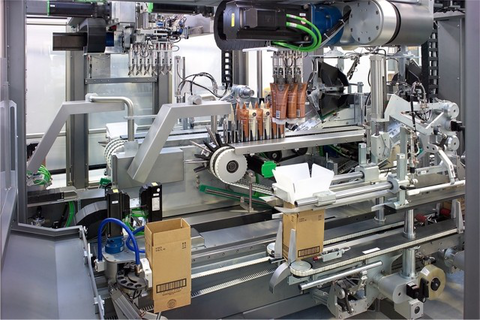

IF318 fully Robotized Monoblock Loading Unit

IF318 fully Robotized Monoblock Loading Unit

CAMA GROUP proudly show-cases its latest Break-Through Generation (BTG) systems.

Cama’s new IF318 ROBOTIZED MONOBLOCK LOADING UNIT includes the latest technological innovations by CAMA Group and marks an industry milestone with the highest standard of Research & Development in packaging automation.

The fully robotized IF318 monoblock carton forming/loading/closing system packs food and non-food products into paperboard or corrugated carton or case. On this innovative “pitch-less” integrated platform, working with a given product infeed capacity, you are free to change the number, and so the pitch, of boxes handled at each of the 3 stations. Each operating station is robotic and de-coupled from the other ones, thanks to the independent electronic movers of the iTrack platform.

In the forming station, the robot picks up the flat blanks from the magazine and forms cartons, which are then conveyed, held on the movers, to the buffer zone, where they wait – in the desired quantity – before moving up to the loading station. A multiple pockets racetrack in-feed system conveys products, which the second robot picks and loads into the cartons, in the required configuration. Moving through the following buffer zone, the loaded cartons are finally closed (in the set quantity) in the closing station, with a final glue stream.

Looking at the specific system, some important technical solutions stand out for smart innovation:

-Pitchless box indexing system, the heart of the whole system, allowing 3 independent phases (forming, loading, closing) from each other.

-Innovative variable box handling device, which allows automatic changeover for all required carton/case size along the track, notwithstanding their shape and size, thereby making size changing useless!

-100% Fool-proof size changing, allowing the operator tooless format changes for both robot heads and machine components, in a safe and unmistakable manner.

CAMA, with this last innovation, introduces to the world market the first secondary packaging system that has true hygienic design! -

IG Complete Robotic Line

IG Complete Robotic Line

CAMA GROUP MARKS A NEW MILESTONE IN R&D. NEW HIGHER STANDARDS WITH THE LAST BREAK-THROUGH GENERATION SYSTEMS

The IG Complete Robotic Line to pack flowpacks in multi-flavour and multi-layer different collations, sold to a global multi-national leader in its sector, will be shown with agreement by Cama’s Customer. The system comprises of two robotic units in line.

The infeed products come in primary packages (flowpacks) on two lanes, one lane for each flavor. The dual-lane conveyor runs down to the center of the Cama IG270, where four Delta Triaflex robots pick the products, mix the different flavours in several different layers configurations and place them onto a special conveyor. This conveyor takes then the products - so collated in single-layers - to the following IG273 loading unit. Here, a 3-axis robot loads these products layers collations into empty trays, previously positioned by a Cama phasing unit. Loaded trays finally run on the conveyor up to the line outfeed point.

The impressive features of the new Break-Through Generation models clearly explain the reasons why Cama has been able to make a step change in innovation in secondary packaging machinery, and to successfully expand in new markets all over the world.

The very last technological innovations by CAMA Group mark a milestone in R&D, raising the standards in packaging automation.- Higher Hygiene Standard

- No hollow body

- No horizontal surfaces

- No water/dust/dirt retention

- No tie wraps

- Easily identifiable contamination

- Easy cleaning

- Open Profile

- No bundled cabling (ICR, Integrated Cable Routing)

- Safe «Easy Entry» and Ergonomics

- Zero «unsafe» Access

- Increased accessibility

- Flexible Frame and Reduced Footprint

- Flexible modular configuration to better suit machine and factory layout requirements

- Cabinet-free technology

- Optimization of floorspace

- Energy Saving Engineering

- Optimized system design and components selection to reduce energy consumption

- Fool-proof Sizeparts Recognition

- User-friendly, fast and tool-less changeover

- Reduced start-up time after changeover

-

Cartoning Machines CL Series

Cartoning Machines CL Series

A NEW SIDE LOADING CONCEPT, PART OF THE BREAK-THROUGH GENERATION

A new Side Loading concept was engineered in Cama to offer the maximum flexibility and efficiency. According to Cama, the System meets expectations of those customers looking for a solution able to work with different speeds, product sizes and at times relevant product variations and carton dimensions. This is not simply a New Cartoner, but a COMPLETE SYSTEM which could be an alternative to a Cartoner and a Top Loading Unit.

DETAILED DESCRIPTION

Cama has introduced the CL175, a new cartoning machine, which has been completely redesigned, both in layout and functioning. Cama’s new side loading cartoner offers maximum flexibility with minimal changeover. Going into details, the CL 175 consists of three main operating stations: in the first one, the carton box is picked from the storage station, opened and placed into the movers’ pockets. After that, it moves to the next station for the product insertion. Two boxes at a time are picked and placed in continuous motion, with movers adapting their speed to the rotary feeder’s one. The boxes remain instead in a stand-by position to receive the items. As this step is completed, the carton boxes are moved towards the final closure station, which can work in continuous or intermittent mode. "The movers are electronically aligned with the devices operating in the different stations; they move independently of each other and adapt to different speed requirements”, Panepinto, Operations Director at Cama Group, points out.

-

Vision driven naked products Pick&Place

Vision driven naked products Pick&Place

Cama’s unique approach with this new multi-robot application provides a single controller for the entire system

Top Speed Multi Delta line in a reduced footprint

One way straight to full efficiency

Cama has been continuously investing in R&D. At least 5% of the yearly Cama turnover is dedicated to Research & Development, because to be a leader means to be able to satisfy the new challenges coming from the market while taking advantage of the latest technological improvements. For over 20 years, Cama has been engineering and manufacturing its own robots, in order to provide one sole supplier secondary packaging systems. The main advantages of this philosophy follow:- One sole supplier responsible for both packaging machines and robots.

- No “black boxes”, thanks to open software together with an instruction manual.

- Robots conceived for the packaging business manufactured by a packaging specialist.

Currently, Delta type robots are playing a major role in the packaging business, thanks to their versatility. Once again, Cama is leading the path with unique and highly reliable solutions.

The picture provides a great example of Cama’s capability to innovate, enhancing a standard system to produce at maximum efficiency. 12 Delta type robots, RB588 model, are integrated in a single loading unit cell. The robots are placed 6 by 6 in two parallel lanes, share the same working area as they pick and place products from the product transport conveyor. Thanks to the Cama patented anti collision system, each robot knows its position and the position of the robots around, avoiding any conflict in picking and placing. The picked products are then placed into trays moving in the same direction as the products, resulting in a co-flow principle which, by means of an accurate software developed by Cama software specialists, guarantees the full fill of all the boxes/trays. One single artificial vision camera drives all the 12 robots. The Co-Flow by Cama is the fastest way to achieve efficiency.

Primary advantages of the Cama robotic application:

- Optimal, fast and gentle-handling solution that proved not to damage delicate products such as naked chocolates.

- Easy handling of extremely irregular chocolates, guaranteeing minimal waste of products.

- The Cama Smart Vision System that optimizes the management of the product by automatically selecting products according to pre-established dimension and arrival speed.

Cama’s unique approach with this new multi-robot application provides a single controller for the entire system, based on a standard technology that can be managed by a trained engineer. Consequently, all functions are integrated in one control system, while the number of interfaces and component costs are reduced.

-

-

-

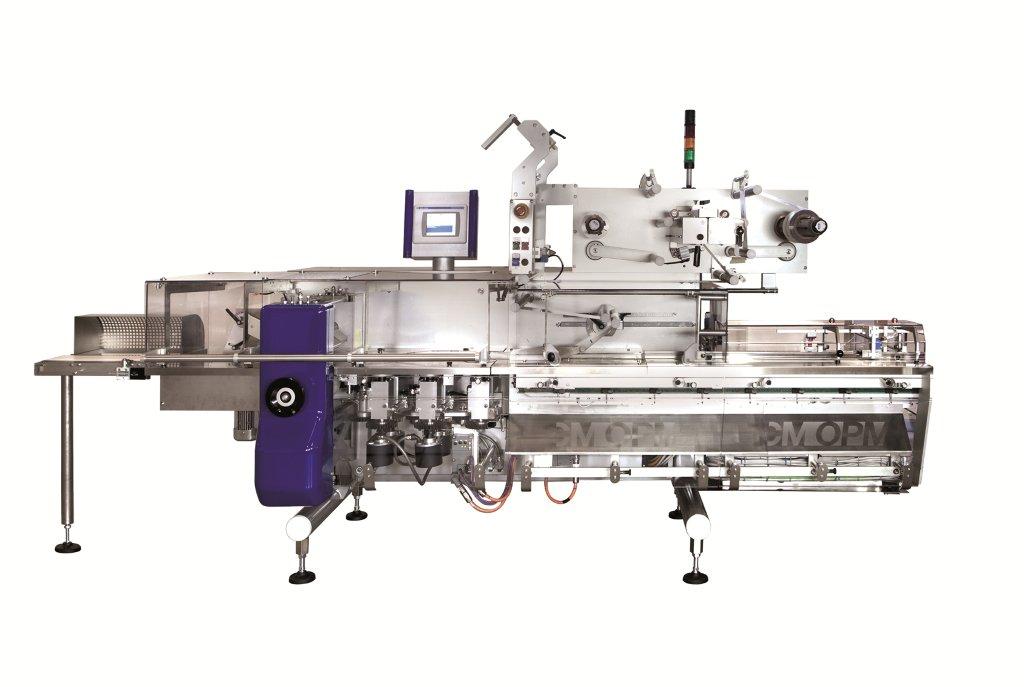

JT PRO

JT PRO

Designed for easy integration on automatic lines, JT PRO is completely servo-driven and it has been rationalized in order to improve the cost/performance ratio.

- Highly ergonomic and maintenance friendly

- Long dwell crimper option available

- Designed around the basics of TPM principles

- Highly modular design

- Available in the F (base) and A (fast) versions

- Available in right-hand and left-hand versions

-

CCI

CCI

Standard features:

- In-line case infeed on a powered roller set

- Positive feed by means of two laterally adjustable chains with pusher lugs

- Mechanical device to fold the transversal flaps

- Adjustable folding shoes to fold the longitudinal flaps

- Automatic glue dispenser for hot-melt glue strips, with distributors fitted on adjustable trolleys with position indicator

- Compression unit to guarantee a perfect adherence of glue points

- On-board electrical cabinet

- HMI touch panel interface for recipe selection, fault display and parameter editing

Optionals:

Tape case closing optional, which folds automatically the 4 upper flaps and applies a U seal of pressure sensitive tape on the top and bottom seams of the cases

-

PNM - PNM/C

PNM - PNM/C

Complete range of automatic mixers for dosing and mixing chocolate masses, creams and compounds consisting of solid, powder or liquid raw materials, such as refined sugar, crystal sugar, cocoa, butter, milk, etc.

The PNM mixers are able to optimize the mixing cycle thanks to a series of special features starting from the precision of the electronic dosing system (using load cells) up to continuous feeding of the refining lines.

-

-

-

-

Metal detector System for liquids and viscous products, past

Metal detector System for liquids and viscous products, past

Metal detector designed for installation in food production environments where there is a need to inspect liquid, paste and slurry products as they travel through process pipelines. Is the perfect solution for the inspection of the following product types:

Soups, Sauces, Jams, Dairy

Pipe Connection: SMS, DIN, CLAMP

-

METALIM TOR-AL for miced meat

METALIM TOR-AL for miced meat

The METALIM TOR-AL metal detector is composed by a Comp-Al electronic board that controls the whole system and by a TOR-AL transducer with a circular passage.

The metaldetector is normally installed on a supporting structure: the product to be checked passes through the passage inside a pipe. Furthermore, CO-EL designs and manufactures stuctures following the client's specifical requests.

Automatic ejection valve available!

-

METALIM TUNN-AL

METALIM TUNN-AL

The METALIM TUNN-AL metal detector is composed by the Comp-Al electronic board that manages the whole system and by a TUNN-AL transducer.

The metal detector is normally mounted on a conveyor that transfers the product through the metaldetector's passage.

The metal detector can be fitted with many accessories such as rejection systems.

COEL metaldetector are completely customizable to meet each client's requirements. Alternatively, we sell the metaldetector head alone for installation on pre-existing devices.

-

-

-

-

1002 - Vertical cartooning machine

1002 - Vertical cartooning machine

The vertical cartooning machine 1002 is designed to process multiple products: powdered and frozen products, short cut pasta, sweets, sugar, salt, dried fruit and vegetables, animal feed, seeds, etc.

-

C35 SA - Vertical carton forming machine

C35 SA - Vertical carton forming machine

C35 SA vertical carton forming machine is the stand-alone version of the C35 BS model as well as the optimal solution to adapt a flexible carton forming machine, suitable for the pharmaceutical market, to the customer’s line needs.

-

1001 - Vertical cartooner

1001 - Vertical cartooner

The vertical cartooner 1001 is designed to process multiple products: short cut pasta, rice, sweets, candies, chewing gums, chocolates, chocolate powder and oatmeal, cereals, dried fruit, dried vegetables, pet food, seeds, etc.

-

-

-

Vibrosifters

Vibrosifters

The Cusinato Vibrosifters are versatile and reliable, very important attributes for this type of machine, which is subject to a significant amount of mechanical stress. Modern and sturdy, built with top quality components: the full range of Cusinato Vibrosifters guarantee a long life with maintenance reduced to the minimum.

-

Storage silo systems

Storage silo systems

Cusinato offers Silos manufactured with an exclusive system: a robust metallic weight bearing structure designed to carry product loads of particularly high weight, also considering the feeding systems (Belt or Bucket Conveyors). Cusinato has also developed an exclusive system for the fixing of panels, which prevents the formation of cracks due to the inevitable natural expansions and temperature changes of the environments in which they are installed, avoiding product leaks or stagnation.

-

Patented pivoted bucket elevators and conveyors

Patented pivoted bucket elevators and conveyors

The Cusinato bucket conveyors are ideal for transporting fragile or delicate granular products such as: long and short pasta, legumes, dried fruit, candy, frozen food, pet food, chemical and granular products in general. They are available in different sizes and types to solve every vertical and horizontal transport problem. Each machine provides maximum reliability over time with a minimum level of maintenance and full respect of the load.

-

-

-

COLORADO 660 PP/PE – Vertical form, fill & seal machine

COLORADO 660 PP/PE – Vertical form, fill & seal machine

COLORADO 660 PP/PE, controlled by PLC. General technical characteristics:

- Main Structure made of varnished steel;

- Electrical cabinet is fixed to the machine;

- Motorized film-reel unwinding system;

- Motorized film-pulling unit;

- Self-centering reel holding unit;

- Sealing system with 3 independent movements, for a better sealing and for the prevention of the knife breakage;

- Bag length measuring system: Encoder

- End of film automatic detection system with automatic machine pause when the film-reel is over;

- Sealing bar safety device;

- Sealing System: Hot bar (PP) or Impulse Sealing (PE);

- Interchangeable forming tube having. external diameter of max 190mm;

- Max. bag length: 300mm (600 mm by double sealing cycle);

- Max. empty bag width: 300 mm;

- Max width film reel: 650mm;

- PLC control system;

- CE Certification;

- Power Supply: 400V-50HZ-3 phase+N-Ground;

-

ORION 700 E

ORION 700 E

Electronic Horizontal Flow-Pack machine complete with rotary sealing jaws and Film Roll Holder from the top, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

- Cantee lever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2600mm long infeed conveyor (usable loading space 1800mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling , second one is for sealing and third one is for driving.

- Pneumatic opening of the fin wheels;

- One up-rotary motion sealing assembly with 350mm wide jaws and transverse or longitudinal sealing pattern complete with inclined cutting knife assembly . Sealing surface width 12,5mm;

- Electronic torque limiter on transverse sealing jaws;

- Motorization by means of 3 brushless motors ,one for the infeed conveyor, one for fin wheels assembly and one for transverse jaws assembly;

- One self centering cantilever film roll holder 700mm wide from the top;

- Discharge conveyor belt one meter long complete of independent motor controlled by inverter;

- Shock proof Plexiglas safety guards with safety micro switches;

- Color touch screen with the possibility to store up to 99 working programs;

- On adjustable or one fixed forming box;

- Machine direction from left to right as shown on general catalog;

- Pneumatic components: FESTO;

- Machine built in accordance with CE standards;

- Voltage: 400V , 3PH , T+N

-

YUKON – Vertical bagger

YUKON – Vertical bagger

Vertical form, fill and seal machine, model YUKON PE with centre folded film controlled by PLC Siemens.

- Main Structure made of varnished steel;

- Electrical cabinet is fixed to the machine;

- Pneumatic reel-holder shaft;

- End of film automatic detection system with automatic machine pause when the film-reel is over;

- Motorized film-pulling unit;

- Film-unwind process is carried out by a toothed belt coated in Linatex;

- N.1 Loading station fully respecting the ruling safety norms;

- Pneumatic unit for horizontal sealing and cutting processes, with sealing band and knife;

- Pneumatic unit for vertical sealing and cutting processes, composed of a hot bar fit to an adjustable sliding block;

- Bag length measuring system: Encoder

- Exit conveyor belt, which holds and leads the already made bags outwards. It can be adjusted (up/downwards) according to the vertical size of the bag;

- Film pulling device for wasted film;

- Max. bag length: 500mm;

- Max. empty bag width: 480 mm;

- Max film reel width: 570mm.

- PLC Siemens control system;

- CE Certification.

- Power Supply: 380V-50HZ-3 phase+N-Ground.

-

-

-

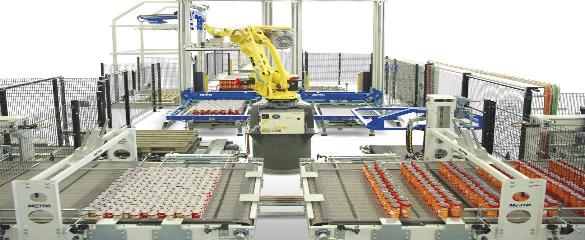

Robot cells

Robot cells

The multisector DUETTI past, present and future experience in developing customized robot systems for palletizing and case packing, ensures the already solid know how base continuously expands

Why use an anthropomorphic robot?

- Improve product quality and consistency

- Improve working conditions for personnel

- Increase production

- Increase production flexibility

- Reduce waste and increase earnings

- Improve safety in the work place

- Limit demand for specialized personnel

- Reduce capital costs increasing efficiency

- Save production space

DUETTI is able to develop a project studying the best solutions in terms of flexibility, productivity and space. The pick-up heads are the result of years of experience and can be custom designed or modified depending on the product to be handled.

A innovative design combined with the wide possibility for auto-programming make these systems an important investment for the integration of future production lines.

-

Depalletisers

Depalletisers

The depalletising solutions break down into the two main categories: Layer or inflatable tubes depalletisers

- SWEEP: transferring a whole layer of product at a time the pallet to an outfeed table; stability and integrity of the product during transfer is ensured by a series of supports.

- INFLATABLE TUBES: depalletising of the product by pick-up and deposit with cartesian movement. The system uses a gripping head with inflatable tubes for rows of products for a stable transfer of the product.

- SWEEP: transferring a whole layer of product at a time the pallet to an outfeed table; stability and integrity of the product during transfer is ensured by a series of supports.

-

Automatic Carton closers and units

Automatic Carton closers and units

The carton closing modules manufactured by DUETTI are automatic machines for top closing/sealing of the American (RSC) cartons by ADHESIVE TAPE or HOT-MELT GLUE. Some models are also suitable for sealing both the upper and lower carton flaps if this has not done before.

Lid/cover forming and positioning modules for open (HSC) cartons or display boxes are also part of the range.

-

-

-

Printing on objects

Printing on objects

CODITHERM, PRINTING EXCELLENCE

Coditherm printers are designed in the Eidos research and development workshops to implement the advantages of digital printing flexibility on industrial products. By implementing clean and environment-friendly methods, Coditherm can be used to print small batches with variable data (dates, forward or backward number sequences, texts, lists of ingredients, barcodes, two-dimensional codes, logos) directly on plastic surfaces, porous materials, irregular substrates, rigid and round objects without interrupting the production process and guaranteeing object traceability.

SAVING

With Coditherm you can print variable data without needing to store plates: real-time printing and the result is immediately dry and clean without needing particular drying processes.

FLEXIBILITY

Coditherm is ideal for marking variable data on small batches. A wide range of thermal ribbons are available in an array of colours for all applications. A complete set of alphabets, numbers and logos allows to create all data settings.

INTEGRABLE

Coditherm may be supplied as printing head or pre-fitted on a desk support with sliding device and guards for semi-automatic operation. It is suitable for replacing hot or pad printing. No particular changes to the packaging machine are needed.

QUALITY

Thermal transfer technology guarantees high-definition printing which is resistant to frequent washing, scratching, rubbing and external elements, such as oil, petrol or alcohol.

SIMPLICITY

With an integrated electronic unit and touchscreen, you can adjust printing parameters or edit data retrieved directly from the memory of the device, from a USB flash drive or a connected computer.

VARIABILITY

Coditherm can print on surfaces with very different compositions and features, such as plastic, smooth wood or leather, fabric or thick coats of paint on metal.

-

Printing on film

Printing on film

SWING, FAST PRINTING SYSTEM

Thermal transfer technology makes Swing an ideal solution for overprinting variable data (dates, forward or backward number sequences, text, lists of ingredients, barcodes, two-dimensional codes, logos) on plastic film or paper. A solution which allows to print directly on the production line, to the advantage of printing speed and quality.

SPEED

With Swing you can print up to 1000 mm/s or up to 350 prints/minute for high-definition applications (up to 12 points/mm - 300 dpi) without ever stopping the production line.

SAVING

With the thermal transfer printing you can change the head without changing the plate. And you can save thermal transfer ribbon by using the ribbon saving functions.

FLEXIBILITY

Swing has a bracketing system ready for the most popular machines on the market and comes in a variety of models according to the operation of the packaging machine.

SIMPLICITY

With Swing you can print variable data on small batches or intervene on the printing parameters directly on the touchscreen, by connecting to a computer or by using a USB flash drive.

-

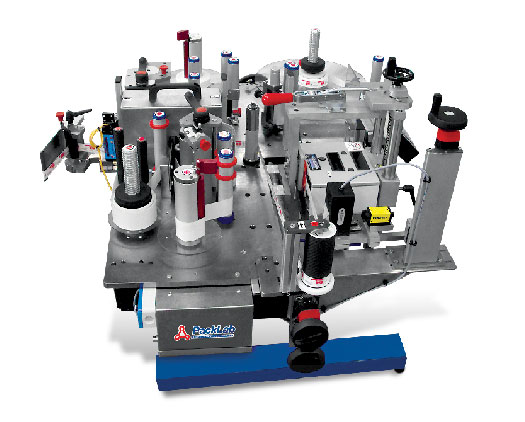

Printing on labels

Printing on labels

PRINTESS, THE LABELLING ROBOT

Printess is the result the expertise of Eidos in designing and making thermal transfer printing systems. It is a labelling robot for automatically printing and applying labels quickly, reliably and safely. It is robust and ideal for industrial environments.

SPEED

Printess can print high-definition self-adhesive labels (300 dpi) at high speed (up to 500 mm/s) applying them directly onto stationary or moving objects moving very precisely.

INTEGRABLE

Printess printers implement SATO and ZEBRA standards allowing integration on all packaging lines with no problems of compatibility.

MODULARITY

With the integrated printer and applicator system, you can choose from an extensive range of applicators and modules designed, developed and tailored by Eidos for specific needs.

SIMPLICITY

Variable data can be invoked directly on the production line on the touchscreen connected to a remote PC or uploaded from a USB flash drive.

-

-

-

Packaging machine F1000 + volumetric belt doser DT10

Packaging machine F1000 + volumetric belt doser DT10

FROM 5 TO 30 kg

Packaged products: sand, lapillus, perlite, gravel etc.

-

Packaging machine F1000 + weigher with dual feeding Auger B/

Packaging machine F1000 + weigher with dual feeding Auger B/

FROM 5 TO 25 kg

Packaged products: spices powder, flour, milk powder, powder for confectionery, chemicals , plaster, cement, pre-mixed for building, etc.

-

Packaging machine F700 + Vertical Auger DOSER DV5000

Packaging machine F700 + Vertical Auger DOSER DV5000

Packaged products: spices powder, flour, milk powder, powder for confectionery, chemicals , plaster, cement, pre-mixed for building, etc.

-

-

-

Skilled 504

Skilled 504

The SKILLED 504 is an electromechanical robot with articulated cinematic structure type SCARA with 4 interpolated axes, and a working area of 360°.

-

Skilled 304

Skilled 304

The SKILLED 304 is a 4 axis articulated arm type robot with 310° degree work area access. It is the best of the European Technology: German innovative “muscle” from KUKA with components in carbon fibre composite (CRP) for lightness with strength and the electronic & software “brains” from SKILLED by EUROIMPIANTI for accuracy and convenience.

-

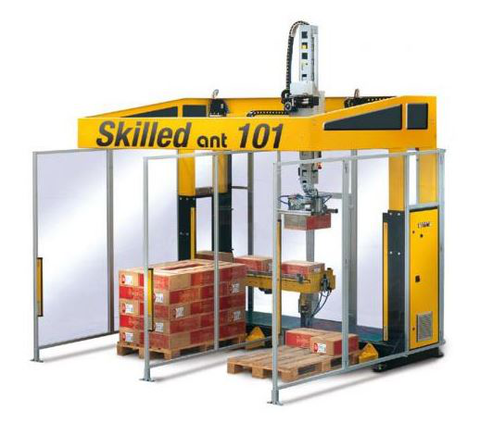

Skilled 101

Skilled 101

SKILLED ant 101 is a very simple palletizing robot that requires no installation; it has a modular construction and can be adapted to any pre-existing product conveyor and packaging line. SKILLED ant 101 can be trasported in a standard container and, on delivery, the machine is completly assembled and ready for use.

-

-

-

-

Aseptic filling

Aseptic filling

...of presterilized bags

With over 600 aseptic plants sold worldwide, FBR-ELPO is considered a leading company for the manufacturing of aseptic fillers for liquid, pasty and concentrated products as well as for products with pieces, based on tomato, fruit, milk and its by-products. Aseptic bags with 3, 5, 10, 20, 200 and 1.000 liter capacity are used.

FBR-ELPO fillers, easy to use and completely automatic, can be manufactured with a filling system by means of a flow-meter or with loading cells, using all caps and spouts existing on the market; the sterilization is carried out with steam or with a disinfectant chemical agent or with sterile air.

The whole production cycle is controlled by an “Intelligent Vision System” (IVS) consisting of an Industrial Touch Screen PC and a PLC.

The Bag-in-Box range for filling 3, 5, 10 and 20 liter aseptic bags, with operating capacities up to 10.000 l/h, is highly appreciated in the dairy sector where FBR-ELPO has gained great experience thanks to the manufacturing of equipment for filling milk and its by-products, milk-shake, mousse, cream, for the most important brands of the field.

FBR-ELPO also manufactures ultra-hygienic fillers for the automatic filling of web bags provided with cap/dispenser for products such as wine, oil, water and other liquids and/or semi-thick products which do not need to be aseptically filled.

FBR-ELPO fillers can be coupled to tube-in-tube, scraped surface, plate or flash cooler sterilizers.

-

Fruit Processing

Fruit Processing

Processing lines and concentration plants

The experience gained with the processing lines for continental and tropical fruit, has let FBR-ELPO consolidate its presence worldwide, manufacturing cutting-edge equipments for the production of:- pulpy juices, clear juices and/or nectars

- natural, semi concentrated and concentrated purees

- diced fruit, treated also aseptically

- jams

-

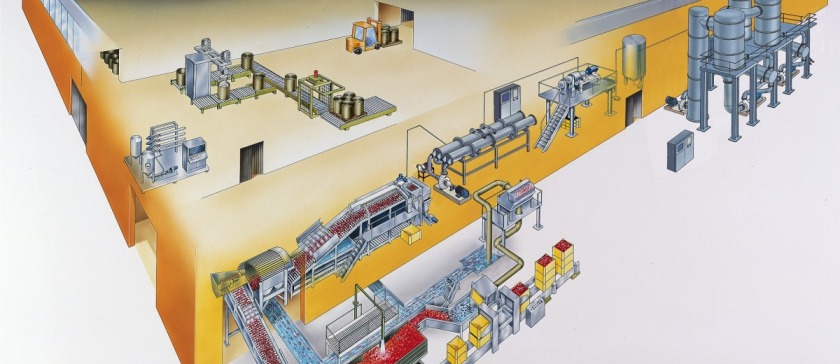

Tomato processing

Tomato processing

Processing lines and concentration plants

In order to obtain an excellent finished product, the raw material has to reach its destination in the shortest time, thereby reducing the stress it has already undergone during the mechanical harvesting and its transport to the factory.

To safeguard the tomatoes to be processed, it is advisable to adopt the most suitable solutions for the unloading, washing and sorting operations. For this reason the machines composing the different sections of the processing line have to be conveniently combined.FBR-ELPO manufactures machines for the production of:

- tomato puree

- tomato paste

- diced tomatoes

- tomato pulp

-

-

-

Multi-function robotic systems

Multi-function robotic systems

ZEUS is a flexible robotic system able to satisfy the packaging needs for almost all container and pack types and sizes thanks to the wide range of its special lifting heads. ZEUS peculiar features make it the best alternative to the traditional systems for containers handling, palletizing & depalletizing and crating.

-

Pasteurizing, heating and cooling tunnels

Pasteurizing, heating and cooling tunnels

The FMT company, with over a hundred pasteurisers installed all over the world, is recognized as a leading company of the sector.

The easy functioning and maintenance as well as the quality of the treatment made, make of FMT pasteurisers an ideal solution to carry out pasteurizing, heating and cooling cycles on glass and plastic bottles and cans. The FMT's tunnels are suitable to handle all containers. The modular design allows to customize the machine for many applications.

The innovative and well established know-how concerning the accumulation control of pasterurising units (UP) also known as ACSPU (Automatic Control system of pasteurizing units) permits the temperature control right there where the UP are accumulated (bactericide effect) and the maximum value of loaded UP, minimizing the energy and cooling water consumptions.

-

Capping machines

Capping machines

Our capping machines, entirely manufactured in stainless steel, have been designed to allow the capping, both with and without vacuum (steam technology), of glass jars and bottles with different kind of caps. The capping machines can be supplied together with the caps feeders, which model is selected depending on the specifc needs of the customer.

-

Pocket Fillers

Pocket Fillers

Our telescopic fllers are ideal for the flling of glass and tin plate containers with solid, diced, sliced and granular products, such as mushrooms, mais, peas, small vegetables, fruit salads, cherries etc.

-

Vibration linear fillers

Vibration linear fillers

Our vibrating linear fllers (series RVL) are suitable to fll the glass and cans with with whole or diced fruit or vegetables, such as cucumbers, onions, pickled vegetables, olives, artichokes, mushrooms etc.

These machines are extremely versatile and require no tool changes for the different formats productions.

-

Filling & seaming synchronised groups

Filling & seaming synchronised groups

Synchronized groups of filling and seamers. Wide range of filling systems suitable for different applications.

-

-

-

-

RO 3003 P

RO 3003 P

Rotary sealing machine for all types of heat sealable materials for packaging of heavy duty bags.

It stands out in the crowd for its extraordinary flexibility in use, and its capability of working with all types of heat sealable materials.

It guarantees a sealing width of 15 mm on bags in PE, Polyester-PE, AL-PE, PA-PE.

Designed to be the sealing station in automatic packaging lines, or used as independent heat sealer.

Max speed up to 20 mt/min., dual temperature control through digital temperature controllers, Cooling by forced air · Seal pressure adjustment.

Supplied on stand with locking castors with adjustable in height sealing head, electrical components and control panel are in a remote control box mounted away from the sealing head.

-

RO 3001 P

RO 3001 P

High speed rotary sealing machine for all types of heat sealable materials, for packaging of a wide range of products, from food to chemical/pharmaceutical to parts and assembling etc.

Built in stainless steel.

It stands out in the crowd for its extraordinary modularity in use and its capability of working with all types of bags made in flexible heat sealable materials.

-

TS P

TS P

Heavy duty highly flexible impulse sealer, to be used with polyethylene and aluminum or paper coated sacks.

Activated by three closing electromagnets.

8 mm width sealing as from DIN rules, to seal also sterilized pouches.

Separate adjustment of sealing time and temperature.

Also supplied mounted on adjustable stand with locking castors, it can be easily installed anywhere alongside packaging lines.

-

-

-

Pie Production Line

Pie Production Line

GEA Tartomatic is the most compact and flexible pie machine on the market for production of a wide variety of pies and tarts in different shapes and sizes. The key part of the machine is the extruder that guarantees the gentle and efficient handling of dough and the highest available volume accuracy. The high-precision stamping process ensures perfect pie shell, with exactly the right dimensions and thickness, for consistent product quality and weight. Also on show will be an integrated volumetric piston depositor for cream or jam for producing classic tartlets.

-

Complete cupcake production line

Complete cupcake production line

Seen on show for the first time will be the GEA Comas high-capacity cupcake production line mounted on a GEA Imaforni tunnel oven. This part of a complete cake production plant on the GEA booth will include: a high-speed rotating paper cup dispenser to deposit self-supporting paper cups; a high accuracy volumetric multi-piston depositor with brushless motors and interchangeable head for easy washing and fast product changeover; and a convection tunnel for perfect baking.

-

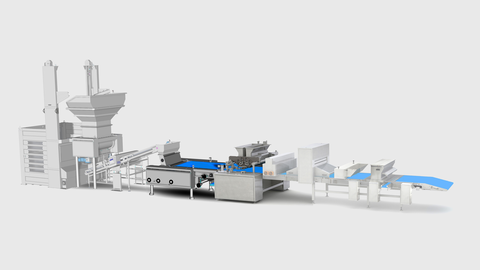

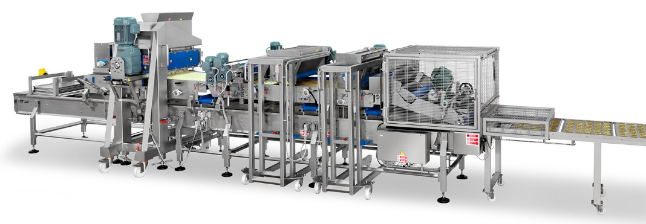

New integrated system for soft biscuit and cookie lines

New integrated system for soft biscuit and cookie lines

GEA’s experienced staff will show an integrated system comprising a GEA Imaforni rotary molder for soft biscuits combined with a GEA Comas co-extruder machine for cookies. This new solution provides even the most demanding customers with a flexible production line for a huge variety of rotary biscuits, wire-cut cookies, smooth biscuits, two-color center-filled cookies and fig-bars. The GEA biscuit and cookie line offers high performance and excellent accuracy in every biscuit; this results from GEA’s extensive experience with a worldwide installed base and a constant effort to satisfy customers’ needs.

-

-

-

GSP 55 EVO

GSP 55 EVO

GSP 55 EVO is the result of our machines' evolution and of many experience's years in the field of horizontal products' packaging.

Electronic Horizontal Pillow Pack Wrapper, versatile and reliable, very flexible in the format-change, suitable for food and non food products, both for single-dose and for multiple packages.

Cantilever frame and easy accessibility, together with sanitation (sanification) principles, easy maintenance and safety, it has been constructed for, allows this wrapper to distinguish itself.

-

GSP 50 EVO

GSP 50 EVO

GSP 50 EVO is the result of our machines' evolution and of many experience's years in the field of horizontal products' packaging.

Electronic Horizontal Pillow Pack Wrapper, versatile and reliable, very flexible in the format-change, suitable for food and non food products, both for single-dose and for multiple packages.

Cantilever frame and easy accessibility, together with sanitation (sanification) principles, easy maintenance and safety, it has been constructed for, allows this wrapper to distinguish itself.

-

Wrapping machine GSP45 EVO

Wrapping machine GSP45 EVO

GSP 45 EVO is the result of our machines' evolution and of many experience's years in the field of horizontal products' packaging.

Electronic Horizontal Pillow Pack Wrapper, versatile and reliable, very flexible in the format-change, suitable for food and non food products, both for single-dose and for multiple packages.

Cantilever frame and easy accessibility, together with sanitation (sanification) principles, easy maintenance and safety, it has been constructed for, allows this wrapper to distinguish itself.

-

-

-

Pre-made sterile pouches

Pre-made sterile pouches

Pre-made z-belt sterile pouches with central saddle for a perfect integration with the aseptic filler. The packages in multilayer high barrier flexible material have advantages of sustainability, convenience, functionality and safety thanks to reduced weight and volume, to special shapes and formats, and to easy opening features.

-

Pre-made Stand-up Pouch

Pre-made Stand-up Pouch

Pre-made stand-up pouch, even shaped with punched handle for an easy grip. Multilayer, high-barrier oxygen-resistant laminate with strong mechanical properties. Rotogravure, high-quality printing makes on-pack communication easier and pleasant and enhances product appearance. Pouches can be sold singularly or in a “z-belt” version, suitable for Goglio’s GNova system.

.jpg)

-

Aseptic Packaging

Aseptic Packaging

Goglio produces a complete selection of flexible packaging in metallized, alufoil, coextruded and transparent materials together with caps and spouts suitable for any kind of product transformed by the food industry.

Hot Filling System

Hot Filling technology allows to package pasteurized products in pre-made pouches. It can be successfully applied to tomato derivates or other products, in formats from 70ml to 10 litres.

Aseptic System

Aseptic technology is conceived to package sterile products in z-belt pre-made pouches treated with Gamma-rays, in formats up to 5.000 ml. The G Novasteril line opens, fills and seals the pouches in the sterile chamber.

-

-

-

Diamond 650 Box motion

Diamond 650 Box motion

The IFP Diamond 650 box motion wrapper is a particularly versatile machine designed to wrap individual products with or without tray using shrinkable or non shrinkable film.

Its cantilivered frame and its great accessibility make the maintenance and cleaning operation very quick and easy. This model can suit your specific requirements and is available in both stainless steel and painted version.

The size range and the continuous rotary side sealing system permit the wrapping of either short or very long items such as profiles or unstable products. Equipped with its standard motorised infeed conveyor it as the possibility to collate multiple packages either in line or side by side. Speeds of 99 per minute are possible with the further possibilities of auto collating and loading.

The option to have this range configured right to left or left to right gives the opportunity of one operator supervising the operation of two machines at the same time. The touch screen permits the storage of up to 99 different programs offering motorised auto size change between different wrapping requirements. Practical and easy to understand controls minimise the time from installation to profitable production.

-

Diamond 650 2 Belts

Diamond 650 2 Belts

The IFP Diamond 650 2 belts wrapper is a particularly versatile machine designed to wrap individual products with or without tray using shrinkable or non shrinkable film. Its cantilivered frame and its great accessibility make the maintenance and cleaning operation very quick and easy. This model can suit your specific requirements and is available in both stainless steel and painted version.

The size range and the continuous rotary side sealing system permit the wrapping of either short or very long items such as profiles or unstable products. Equipped with its standard motorised infeed conveyor it as the possibility to collate multiple packages either in line or side by side. Speeds of 70 per minute are possible with the further possibilities of auto collating and loading.

The option to have this range configured right to left or left to right gives the opportunity of one operator supervising the operation of two machines at the same time. The touch screen permits the storage of up to 70 different programs offering motorised auto size change between different wrapping requirements. Practical and easy to understand controls minimise the time from installation to profitable production.

-

Sleeve And Batch Sealers + Shrink Tunnel

Sleeve And Batch Sealers + Shrink Tunnel

Automatic wrapping machine model TWIN T 75/N with in-line feed system using motorised conveyor belt, oscillating sorting unit for 1 to 6 lines and automatic formation of multipacks.

-

-

-

Buckets Line

Buckets Line

The ILPRA Bucket Line is designed to package a wide range of liquid and viscous products. All models can perform both in sealing only and in MAP (Modified Atmosphere Packaging).

This range of machines are able to satisfy several production needs from low output production runs to high size industry.The Foodpack Bucket Line can be customized with several options, such as snap on lids, denesting units and dosing systems.

All models are primarly constructed of stainless steel AISI 304, due to this the machines can be used in wet environments and for ease of operation and washing front and rear doors of the machine have been designed to give immediate access to all areas.

-

Foodpack Speedy

Foodpack Speedy

The Speedy is the first automatic model belonging to our FOODPACK range of tray sealers.

This model is manufactured in hundreds items every year, and is designed to meet the highest constructive Standards.

The machine is mainly constructed in stainless steel, Class protection IP65, and is conceived to be a cost-effective model. Just few of its strongest points: reliability, easy cleaning and maintenance, a simplified software for working parameters, many available accessories which make the machine fully customized. ILPRA improves the Speedy performance with innovative technology to obtain either low consumptions or capacity increase. For instance the Progas technology, as standard on the FOODPACK range, will reduce the gas consumption of 40% than traditional solutions, while the mechanical Speedy version avoid the cost of compressed air and reduce the maintenance ones.

FOODPACK Speedy Emec is the mechanical version of the FP Speedy and compared to the FP Speedy the FP Speedy Emec has a slightly larger sealing area.

The Emec engineering avoids the cost of compressed air and reduces the maintenance ones.

The FP Speedy Emec is an in-line machine and as the FP Speedy it has been designed in varoious versions of sealing techonology: as sealing only version, vaccum version and MAP (Modified Atmosphere Packaging) verison.

As the FP Speedy even the FP Speedy Emec has been realized stainless steel, class protection IP6. Thanks to the materials used for its manufacturing, the FP SPEEDY Emec is suitable for working in wet and/or aggressive environments.

The Speedy Emec has a suitable structure where it’s possible to place denesting systems, fillers and other options.

-

M7 - Fully automatic high production tray sealer

M7 - Fully automatic high production tray sealer

The machine is available in two versions: N for sealing only and V/G for vacuum packaging or vacuum/gas packaging.

High Technology

The machine is designed with ILPRA E-MEC technology based on electro-mechanical motion of working stations which offers low energy consumption and low maintenance. The Mmodel is designed to be integrated into existing customer’s production lines. The changeover is extremely simple with new mechanical lift system.

The new film unwind system provides high precision both in working and in print centering.The revolving touch screen control panel features a friendly use multi-program storage capability.

Hygiene and complete access

The IP 66 class protection and the stainless steel material the machine is constructed of make the M7 able to withstand aggressive environments, such as factories packaging dairy or brine products.

Complete access to the sealing area is easily gained by lifting both the front and rear doors of the machine. The working table is designed to avoid the stagnation of washing liquids. All the belt conveyors are removable and washable. All that makes cleaning and maintenance operations very easy and quick.

Versatility and customization

To grow the high value for M7 model, a wide range of options and different loading conveyors (infeed continuous or stepping conveyor with single / double line or walking beam conveyor system) are available to make the machine suitable for several applications and to meet specific customer needs.

-

-

-

Corazza - FD Series

Corazza - FD Series

Dosing and wrapping machines for convenience food, i.e. paste soup cubes and yeast

Output (packs p/min): 300 - 1200

Dosing range (g): 9 – 50

-

Wrapping Machines for Butter

Wrapping Machines for Butter

For pasty products. High filling precision and the flexibility to change sizes (footprints) and complete formats (packet shapes).

-

Flexi Bag 280/400 single tube VFFS bagger series

Flexi Bag 280/400 single tube VFFS bagger series

Recommended for medium output, when multiple number of SKU's are to be packed on a single machine. Machine can be upgraded with various dosing systems, based on application. Available in Eco, Servo and Continuous motion.

Output (packs p/min): 120

Types of bags: Viz. pillow, gusseted, block bottom, three side seal, quad pack, penta seal pouch

-

-

-

Lidpack

Lidpack

Lidpack was especially designed to pack stacks of plastic lids, small shallow containers, glass or plastic slides, bearing cages, seals and all kinds of unstable or unstackable products.

-

Palletizer robot

Palletizer robot

Compact, sturdy and rapid palletizer robots ideal for handling objects of different types and weights. It can be equipped with a pick-up head with grippers or suction cups, according to the product type.

-

MCWS 0

MCWS 0

Piece counting/weighing machine particularly indicated for weighing large size hardware such as nails, screws, nuts, bolts, plastic, aluminium casts and miscellaneous small parts. The micro-processor constantly monitors the weighing system to guarantee the set dose at maximum speed.

-

-

-

635-645

635-645

For professional use

The top loading cartoner has been developed to package institutional (food service) rolls of aluminum foil, plastic film and baking paper into cardboard boxes. The carton can be connected to one or more automatic rewinding machines to minimize output, it comprises a carton erector, a compact robot that quickly inserts rolls into cartons, and a carton closing device. Specially designed cartons support the roll packaging without any additional suspension device. No plastic or other core plugs are therefore needed. The blank is designed to minimize cardboard consumption and to reduce carton costs. The ROTO MAC top loading cartoner can be provided with downstream equipment for labeling, printing, bundling and wrapping.

-

705

705

Large: for packaging rolls into cartons

The continuous motion cartoning machine 705 is a high-speed automatic machine. When connected to two or more automatic rewinding machines it guarantees high production speeds and a maximum efficiency and productivity at the production plant. The 705 handles cartons of various sizes and styles with different types of closure flaps.

-

501

501

Small: for packaging rolls into cartons

The intermittent motion cartoning machine 501 is a very small, compact automatic machine. When connected to a single rewinding machine, it is a compact and efficient production unit which can be easily controlled by a single operator. The machine operates only when a roll arrives. It loads the roll into a carton, indexes it to the next position and then stops until a new roll arrives. From here on the cycle repeats itself. The machine is designed for very narrow spaces that do not allow for a conventional cartoning machine. The machine uses single size cartons, folded and pre-glued on the long side with 4 flap closures. Once set to process a certain size of carton, the machine cannot be changed to different sized cartons any more.

-

-

-

Atlantis 70k

Atlantis 70k

Vacuum packing is a process which extracts the air from a vacuum bag before sealing, creating an environment that helps preserve perishable products and prolongs shelf-life.

-

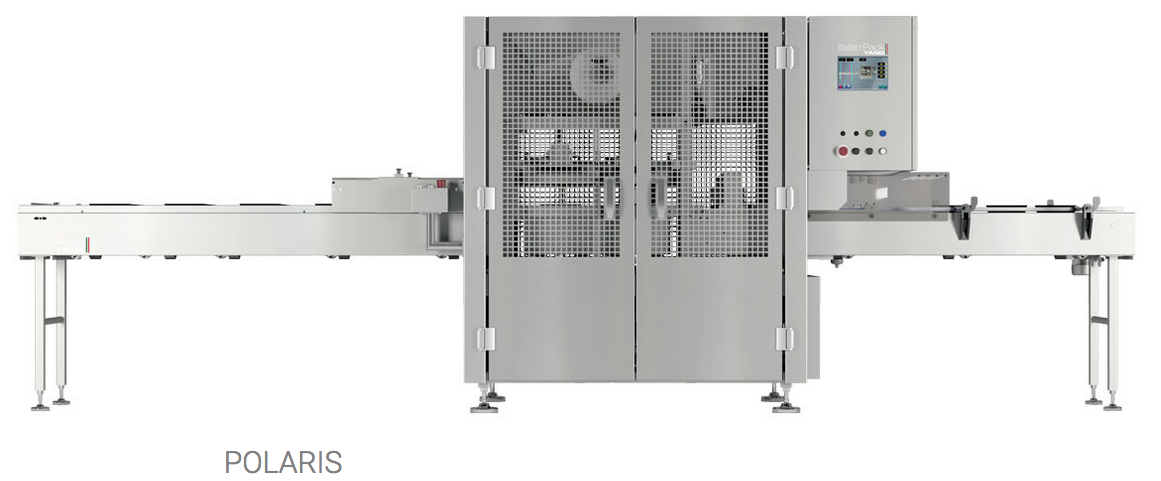

Polaris

Polaris

ItalianPack Polaris One/Double/Tre models are fully automated machines for the vacuum, M.A.P. (vacuum+gas), skin tray and sealing only packaging of pre-formed trays.

The three lines can be equipped with 1, 2 or 3 packaging stations and, depending on the model, with different dies for instant format change or with the same die for double or triple production rates.

Die changing takes less than 2 minutes. ItalianPack Polaris can be ideally configured for each packaging solution and additional equipment options allow for a turnkey "complete line" to meet today’s specific packaging requirements.

Our company’s Engineering Department will assist you by designing and developing infeed and outfeed conveyor lines, tray denesters, checkweighers, dosing machines for liquids and solids, markers/printing machines, aligning devices, etc.

Our Polaris machines can pack up to 70 M.A.P. trays, 150 sealed trays and 60 skin trays per minute.

Our user-friendly touch screen display allows easy monitoring of parameters, storage of up to 99 packaging programs and language selection.

All Polaris machines use the same die, which allows for different types of packaging: film sealing only, M.A.P. and skin packaging.

-

Atlantis Automatica 1000

Atlantis Automatica 1000

Stainless steel chamber with round parts for easy cleaning

7.2" PLC TOUCH screen OMRON, 65000 display colors, USB port/ethernet, 99 packaging programs, language selection

Loading belt with adjastable speed

Nr. 2 sealing bar 1000mm with bi-active sealing

Unblock Conveyor system for easy cleaning

Indipendent sealing bar

Optional conveyor belt with strips.

-

-

-

FPF - Binder

FPF - Binder

The FPF is based on the same concept as the FM but in this case the collating and shrink wrap oven, longer that in the FM series, are two separate units connected together.

This specific model is designed to match the output of the medium - fast PACK automatic packing machines.

-

PACK 50 - Packaging for medium productions

PACK 50 - Packaging for medium productions

PACK 50 is ITALPACK's medium capacity packing machine solution. Simple, strong, efficient. Capacity can reach up to 45 bags per minute.

Production for sizes 500 g (45 bpm) to 2500 g (25 bpm)

-

PACK 25 - Packaging for productions up to 25 CPM

PACK 25 - Packaging for productions up to 25 CPM

Automatic packing machine for ready-made, block-bottom bags

PACK 25 is ITALPACK's entry level packing machine. Simple, strong, efficient. It's the ideal packing machine up to 25 bags per minute and presents all of ITALPACK's pro features of reliability and technological know-how.

Production for sizes from 500 g (25 bpm) to 2500 g (18 bpm)

-

-

-

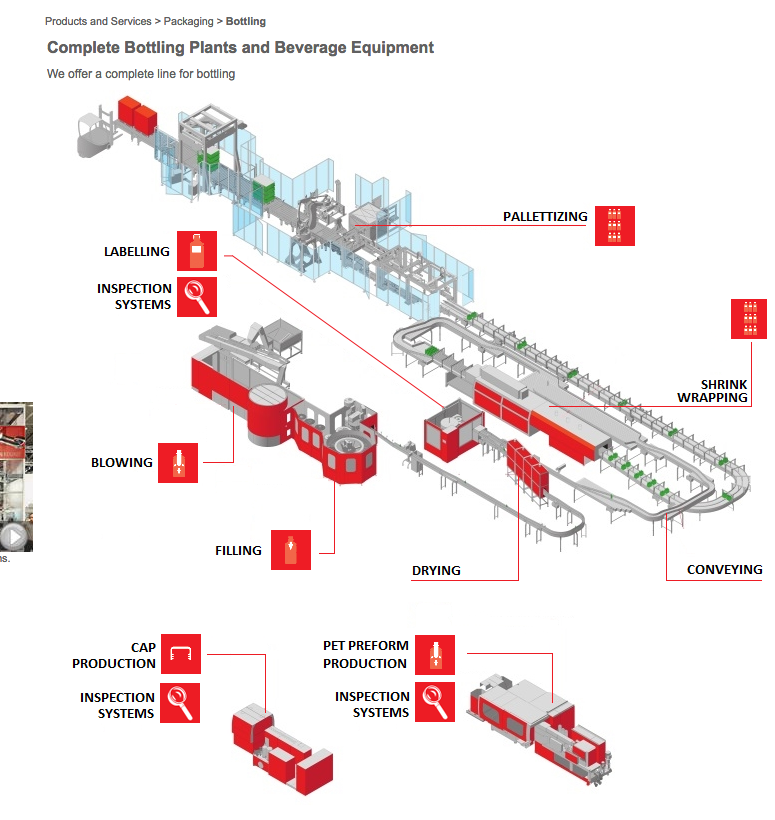

Krones Smartpac

Krones Smartpac

Packing system for one or two pack lanes

In our day and age, there are packs and containers in a vast variety of shapes, but the Smartpac can handle them all. Its assortment of grip-per heads is designed to cope with any and every challenge. And the best thing about it is: All grippers can be changed quickly and easily.

So the Smartpac adjusts perfectly to any task. Even its sequential movements are perfectly synchronised. So it doesn‘t just look good when it is in motion, it‘s also gentle to your products.

-

Krones Variostick

Krones Variostick

Getting to grips with your handles

Even the most minor details can influence the quality, reliability and efficiency of a line – in both a positive and negative way. To ensure that you are not exposedto any risks during the entire packaging process, Krones has developed its own handle applicator for packs. The Variostick can be seamlessly integrated between the packer and shrink tunnel and its many clever details will soon leave you impressed: from its compact modular design and its toolfree change-over process to its trouble-free pack guidance.

-

Krones Varioline

Krones Varioline

More variety for packaging

Today, there are a lot of functional and ergonomic requirements on beverage packagings. The Varioline easily keeps up with this. The flexible system processes not only versatile first and second packagings. It also gives rein to your desire for combinations. You simply select which products should be packed in what way. Varioline will do the rest. Fully automatically, it will compile your required pack at the right time and quantity. Thanks to its modular design, the change-over between different types of packs is performed within minutes. With a rated speed of up to 52,000 containers per hour, the Varioline fits in your line also at high throughputs.

-

-

-

MOTION - meat, piadina, chees, pizza, bread.

MOTION - meat, piadina, chees, pizza, bread.

The box motion cross sealing head allows to obtain hermetic seals for gas flushing packaging (MAP). The perfect solution when an aesthetically pleasing design and high quality gussets are required and in cases of packaging with thick wrapping materials. Bottom reel version available.

Examples of products that can be packaged with this machine

Food: meat, piadina, chees, pizza, bread.

Non-Food: automotive, spare parts, cutlery and plastic dishes (multipack), electrical and hydraulic components.

-

DISKO - candies, chewing-gum, lollipop, pralines

DISKO - candies, chewing-gum, lollipop, pralines

Fully electronic 4 axis high speed machine specifically designed for packaging of candies and hard confectionery in Flowpack style.

The basic version provides single packing of products and can be equipped with proper optional devices to obtain: bags in chain with pre-cutting, multipack, packing of cicklets, packing of lollipops, inclusion of gift (plastic eggs, stickers, cards).

-

COSMIC - biscuits, breads, bakery products, vegetable pans, dairy products, chocolate

COSMIC - biscuits, breads, bakery products, vegetable pans, dairy products, chocolate

Full servo, suitable for manual loading or suitatble to be integrated with low/medium speed automatic lines.

The same strengths of the range’s top machines are applied on COSMIC: balcony frame execution, friendly use HMI graphic software, complete access to the operation area of the machine protected by wide safety cover, wide range of optional.

-

-

-

Roll-forming assembly machine for complex closures

Roll-forming assembly machine for complex closures

Type BLV4-ARV1616 continuous motion rotary roll-forming assembly line for complex closures in aluminium with plastic inserts. The machine complies with the European safety laws (CE).

-

Roll-forming lining machine for aluminium caps

Roll-forming lining machine for aluminium caps

Type BLV8-IRV16DF continuous motion rotary roll-forming lining machine for aluminium caps. Suitable both for inserting double faced Saranex liners and single faced Tin foil liners for wine. The machine complies with the European safety laws (CE).

-

Redrawing machines for aluminium caps

Redrawing machines for aluminium caps

Type RRM10+RRM10L Continuous motion rotary redrawing machine for second and third drawing of aluminium caps. The machine complies with European safety laws (CE)

-

Assembly machine for non refillable pourers

Assembly machine for non refillable pourers

Type ARV16 Continuous motion rotary assembling machine with 1 flywheel with 16 punches for inserting pre-assembled pourers into aluminium caps. Loading stars synchronised with the flywheels.

Discharge star coupled to an ejection system for defective components without stopping the working cycle. The machine complies with European safety laws (CE)

-

Assembly machine for sport caps

Assembly machine for sport caps

Type ARV24/24/24 Continuous motion rotary assembling machine with 3 flywheels with 24 punches each for assembling sportcaps Loading stars synchronised with the flywheels.

Discharge star coupled to an ejection system for defective components without stopping the working cycle. The machine complies with European safety laws (CE)

-

-

-

Mak Roll Feed

Mak Roll Feed

Large volume labeller with wrap-round plastic labels MAK RLF is the new series of rotary labellers for various formats of PET bottle. The use of wrap-round plastic labels on a reel with hot melt application has maximum economic benefits for production with respect to traditional OPP or pre-cut paper la - bels. The MODULARITY of the MAK Roll Feed, a particular feature of Makro Labelling technology, enables the roll feed unit to be replaced with a hot melt unit for pre-cut, wet glue or self-adhesive labels, satisfying the need for maximum production and configuration flexibility. Designed for the high-volume PET labelling market (water and soft drinks sectors in particular), MAK Roll Feed labellers offer a production speed of 6,000 b/h to 40,000 b/h.

-

MAK 2-8: labelling for large numbers

MAK 2-8: labelling for large numbers

The MAK 2, 3, 4, 5, 6, 7 and 8 labellers meet the requirements of medium and large companies: they are equipped with special applications and manage high production speeds. Cold and hot glue, self-adhesive or combined versions are available. Makro Labelling, in perfect synergy with its technical office, is able to develop special machines, fitting special and custom applications upon the customer’s request. The following labels can be applied by these machines: body, neck, neck wrap, back, “I” “L” “U” seals etc, while production speeds vary from 1,500 b/h to 60,000 b/h.

-

-

-

Square bottom bag

Square bottom bag